Copyright © 2019 by Robert Moore · All Rights reserved · E-Mail: droceretik@gmail.com

Kites - which ones and why and how we build them, plus more!

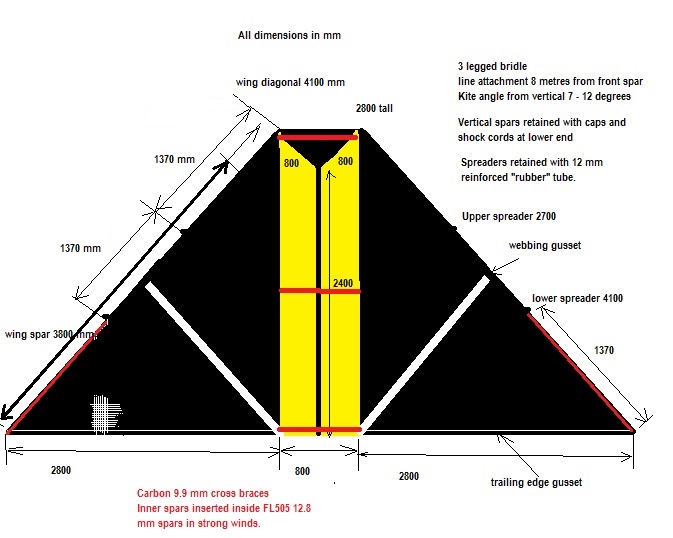

This DT Delta in the front garden at Baulkham Hills, is derived from the kite on the right. This 165 sq. ft. kite was built by Bob Moore from material grade rip stop Nylon and 15 mm fibreglass tube. It was designed for light winds but has proved inferior to the 120 sq. ft. version. This kite has flown to 6,500 ft in October 2005 on thermals. I have decommissioned and used the spars for other kites and the cloth will be used to make children's kites to give away. Kites often don't scale up exactly as the material doesn't stretch to scale nor are the spars proportionally stiffer. In any case the 120 sq. ft. model has reached record height, there was no need to use this kite. A kite of similar size with bigger spars and a double spreader may be the kite to reach 20,000 ft.

Above: DT delta "fast climber" is the basis for my record attempt kites. This version has "scallope" wing tips whereas our version, the Hod Taylor version, has cloth extending the wings to a point.

The Rokkaku or Rok is a Japanese traditional design that many western kite enthusiasts have embraced to build with ripstop and fibreglass. Is a nice flyer in many respects but several flight characteristics eliminate from selection.

The Conyne Delta is a modern version of the Conyne or French Military Kite. Closing the central cell converts it to a DT delta but without the scalloped wings. The central triangular cell gives it extra rigidity compared to a delta design. The Box Delta (below right) has no extra lift compared to the DT Delta but has added weight and drag from the extra longeron and the diagonal cell braces. It may be more stable in theory but this has not been shown in practice to be a significant enough advantage to justify changing from a DT Delta to a Box Delta.

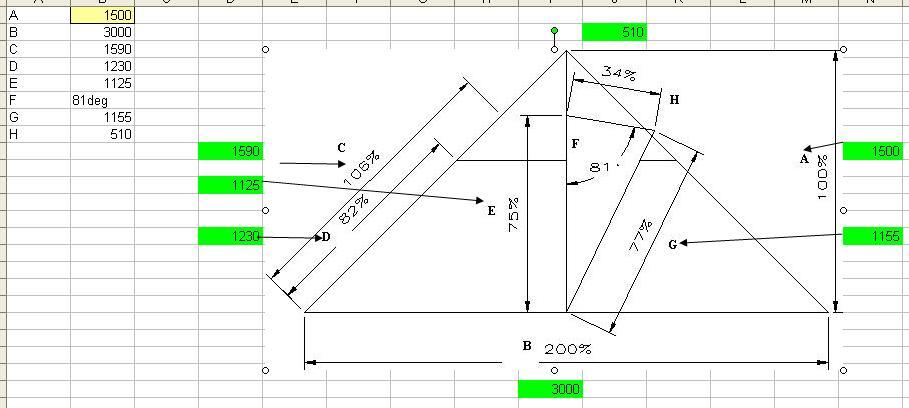

This excel delta kite dimension calculator was developed by Bob Moore to keep the dimensional relationships to scale irrespective of the kite size. Only one value needs entry, that is, the top left at 'A'. then 7 dimensions are automatically filled.

The size of our DT Deltas are somewhat arbitrary and for no technical reason. It's a 4 x scaled up version of red/yellow 30 sq ft DT Delta kite shown in the Rooty Hill image. This kite's dimension were determine by the ripstop width on roll. The biggest influence on the 120 sq ft DT Delta's flying characteristics is the spar lengths and stiffness. The 90 degree angle formed between the leading edge of the wings is derived from an isosceles triangle where the height is equal to half the base width.

This is an original Hargrave Box Kite weighing about 12 lb. Very stable but flys at a lower angle compared to our DT deltas due to higher drag. Note the curved top spars and Hargrave was one of the first to recognise the extra lift of aerofoil profiles.

The parafoil. With a steady wind probably the best kite of all. Very light and tremendous lift from the aerofoil profile. Its Archilles Heel is the tendency to collapse and not recover in gusty and turbulent winds. This kite was used by atmospheric scientist Ben Balsley from C.I.R.E.S. Institude for environmental science in the 1990's.It was 1 of a train of 2 kites which flew to over 10,000 ft from Christmas Island in the Pacific. Image courtesy of CIRES

Steps for building a kite

Our kites are made from 1.5 wt. Rip stop Nylon cloth.

The rolls of cloth are 1.5 metres wide.

Step 1 design

First a scale drawing is either manually done or composed on the computer. I use the Paint program in MS Windows. It is simple and I can experiment with different colour combinations to see which may give the highest visibility against a variety of skies.

Step 2 Colour choice

Light blue would be hopeless against a blue sky. We chose white with a black centre cell so the kite would be visible against a blue sky and against cloud as well. The original kite was black and was reasonably visible against various skies except dark grey cloud.

Step 3 Spar dimensions and cutting.

Fibreglass can split or the strands fragment if not cut with some care. The dust can be hazardous so a mask should be worn. The glass strands can pierce the skin so gloves should be worn. Fibreglass spars must be joined with solid ferrules that are a fairly tight fit. Rubber cement or epoxy can be used if a permanent join is required.

Step 4 template

The next step is to make a 3 ply template of the panels with seam allowances.

If it is a one off construct then a template is not required. The wings on our record kites are equilateral triangles so a template is made with a triangle half the wing size. It can then be used to cut 4 triangles which are then joined. The central section is a large rectangle by cutting two rectangles and joining them.

Step 4 Cutting

The weave of the cloth is parallel to the trailing edge of the wings to minimise stretch and fraying.

The cloth is then hot cut with an electric knife using the template. This hot cutting melts then seals the cloth and ensures accurate cuts and exact replication when building several other kites. We are careful to align the weft and weave of the cloth to maximise lift and minimise cloth stretch.

Step 5 Sewing

The seams and spar pockets are sewn with heavy grade sewing thread reserved for tents, tarpaulins and back packs. Reinforced stress points such as spar ends and bridle attachment points are vital for the kite to survive high winds and the occasional crash. Spar ends have caps to prevent the sharp ends from punching through the spar pockets. Mike Richard's construction has proved very robust. We occasionally need to make repairs and insignia, sticky backed repair cloth is invaluable. It is the same type used on sails for tears. One of the kites survived 59 knot winds without much damage so these kites built by Mike Richard are very robust.

Canadian, Richard Synergy, the previous record holder, used a low aspect ratio Dan Leigh Delta of 270 sq ft. We use kites 1/3 the size but we have exceeded his claimed altitude reached in year 2000 by a large margin. Image courtesy of Outside Online magazine (year 2000)

This a 15 x 12.5 mm carbon fibre tube. the larger dimension is the outside diameter and the smaller, the inside diameter. The stength is determined by a stiffness factor which is measured bu supporting a standardised length of tube between two supports and then suspending a standard weight and measuring the deflection or downward bow.

These are various carbon fibre tubes manufactured in China. The quality is indeterminate and will be subject to sample inspection.

An extracted table from Mike Richards KiteSite shows the specifications and you can see that kite construction costs, especially our big kites, are not trivial. It costs about $500 to make one of our kites and that is cost price without labour charges. Retail it would be at least $1,000. The spars are by far the most expensive part of the kite. Spars, $500, cloth, $200, labour, $300. That's my estimate but Mike Richards may have a different view. (:

The 1.5 OZ/yard ripstop must be used for our big kites. The 3/4 OZ ripstop is for smaller light wind kites. To some extent the kite dimension were chosen because of ripstop widths and the desire to minimise seams and cloth wastage. I did guestimate the size of the kites needed for breaking the record. I proved correct even if i were a bit lucky.

The was the first Hargrave box I made was in 2005 and this is taken at Festival Of The Winds at Bondi Beach in September. The spars look very thin from this distance but are in fact FL505 epoxy fibreglass tubes 12.5 mm (1/2 inch) in diameter. This version is a little taller than the original (right) but has the same sail area and, being built from modern materials, is about half the weight. It doesnt have the curved aerofoil profiles like the original. I have another version which is a slightly different dimension but the same sail area.

I have also constructed the replica below.

This is as near to a replica Hargrave Box Kite as I could build with currently available materials. It also included the aerofoil formers to increase lift. Below it had it's maiden flight at Maroubra Beach with Michael Jenkins providing the pulling power in a gentle south easterly breeze and Roger assiting me at the kite and Michael Richards assisting Michael Jenkins at the pointy end of the line. Below is another view prior to launch.

Roger Martin captured this great image of a great kite with a marker blue sky as the backdrop. Unfortunately Mike jenkins couldn't keep it aloft in a light breeze.

The 3 Hargrave Box Kites together on Bondi beach in 2015's festival Of The Winds and 100 years anniversary of Hargrave's death. The replica is 5.1 kg (11.2 lbs) just a fraction lighter than the original versions. The ripstop and fibreglass versions are about 3kg, about the same weight as the DT deltas we use for the record flights but they have about a 20% smaller sail area. The ripstop versions currently have no aerofoil profile formers to give extra lift but the replica does. How high would the replica fly? Probably 8,000 ft but I have no confidence in estimates. The ripstop version probably woul fly a little higher, maybe to 10,000 ft. As of January 2019, none of these Hargrave Box Kites kites have been flown beyond a few hundred feet.

The Hargrave Box is my second choice for high altitude flying partly because it is a good design but partly because of it's history in Australian and World aviation. it has a few downsides which are difficult in assembling on-field in stong winds and it's lower flying angle compared to a DT Delta. I would make one with carbon fibre and ripstop nylon and use aerofoil formers to improve lift.

Kite building materials

Up to 40 years ago, kites were built with wood dowels, bamboo and other natural materials. The skin was usually made of cotton, nylon, paper or plastic. Long before that, kites were only made with natural materials. These days most modern factory made kites are made with fibreglass rod, tube or for high performance kites, carbon fibre rods or tubes. Most factory and kites built by enthusiast have rip stop nylon skins, some have Icarex which is an extremely light weight fabric. In many Asian countries kites are still made with traditional materials such as bamboo and paper but some modern materials are combined with the traditional. I don't think any kites made with bamboo and paper could reach high altitudes, at least nowhere near the world record, especially using cotton, jute or sisal lines. The German Grund Weather kites used aluminium frames and canvas skins and flew on steel wire but they are the exceptions. Other weather kites around the world used different versions designs derived from the Hargrave box kites. They used wood frames that were heavy compared to modern kites. I can't see any convincing evidence that any single kite in this era flew over 8,000 ft. the Blue Hill box kites flew to over 12,300 ft. but I am convinced the flew a train to that height and not a single kite. As well as the spars and skins, kites need other fittings and reinforcement to make them crash resistant and able to tolerate very high winds. In my case they need pockets for instruments, camera mounts and mounts for strobe lights.

Other kites that deserve an honourable mention with potential for high altitude flight but perhaps not World record altitudes.

The only way to demonstrate that would be be to build large versions of each and fly them to prove what they are capable of that may take months if not years.

Pearson Roloplan, based on a 1930's German design by Steiff. There are other versions of this original design. This one built by Bob moore

A Rokakku, a Japanese traditional design that has been widely adopted by western kite builders and flyers. It is a light to moderate wind kite but in my experience will drop rapidly rather than glide like a delta or DTY delta. 18 "Roks" of various sizes built by Bob Moore. This is one of a series of 16 NRL Roks, 1,200 mm high and 800 mm wide.

A Cody winged box kite from the early 20th century. William Cody flew this big man lifting kites as a showman and adventurer. Based on the Hargrave box kite but adding wings. Resembles the Blue Hill weather kite. May go very high but is complex to build and assemble compared to DT deltas. Polpular build by many enthusiast but i have not constructed one....yet.

A Conyne or French Military box kite. This is the basis for the DT delta but has less sail area so less lift. Probably a high flyer but not nearly as high as our DT deltas.

I built one and it flew well but not that high of an angle. Sail area not not high for spar weights. May be worth constructing another, not for high altitude flight but for festivals.

A very simple kite to build, assemble and fly. A great flyer, second only to the DT delta IMO. I have flown an 8 sq. metre version to 6,500 ft. in light conditions at Cable Downs without trying very hard. May be capable of record altitudes but may not be as robust as the DT deltas. Heavily spared versions tend to be a bit nervous in high winds and are not as stable as the DT delta due to lack of a central cell. Technically they may fly well without a keel but IMO a keel is essential for high winds.

Diamond kites have been a favourite for many years as they are simple to construct from very basic materials. However they are light to moderate wind fliers usually. In the late 19 century some scientist used them to fly instruments to fairly high altitudes (5,000 + ft.). If bowed and constructed carefully they can fly without tails but usually the commercial versions come with a tail because they need them for stability but also for aesthetic appeal. They look pretty and are very easy to fly, even for the youngest child. They are easy to fly as a train of multiple kites on one line. I have built a train of 28. They are not really a high altitude candidate but I could build a big one with carbon spars that may reach 10,000 ft.

Domina Jalbert (1904-1991) invented the ram-air inflated flexible wing often called the "Jalbert parafoil" it has been adapted extensively for numerous roles including military and scientific purposes. Versions of it with different aspect ratios and different cell structures have broadened the applications from sporting to reacretional flying. The modern kite festival would be very difficult to run without the parafoil providing the lift for giant inflatable displays.

Kite Altitude World Record